About Omex

manufacturing

Omex Manufacturing was founded in 1959 as a small, family-run business in Kitchener, Ontario. Omex initially stamped components for the plumbing industry, but our product profile has changed substantially over the years.

Today, Omex Manufacturing has grown exponentially and has established itself as a premier metal stamper and assembler for a diverse group of OEM and Tier 1 automotive customers. We have a world-wide footprint: our products are shipped throughout North and South America, Europe, and Asia. Many of our supplied products perform key functions in the world’s vehicles—adjustable seating mechanisms keep drivers comfortable on every continent; and parking mechanisms are responsible for keeping millions of vehicles stopped and safe when they’re not being driven.

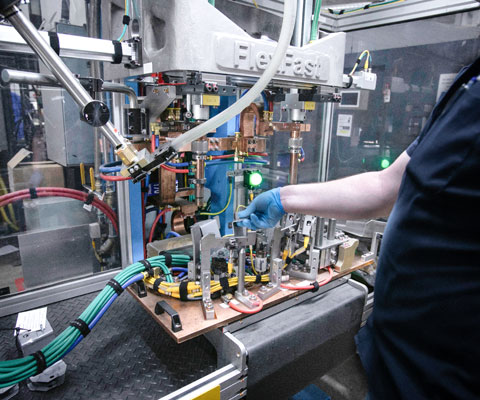

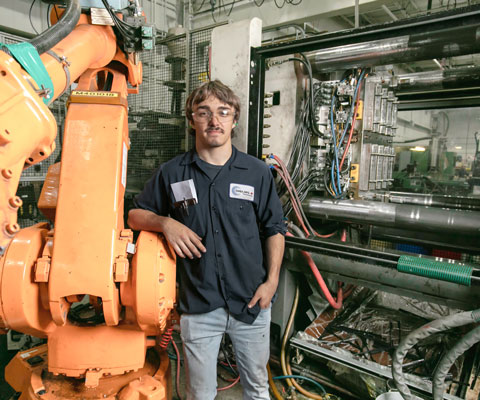

Investing in new and innovative technology has positioned us as a leading manufacturer of difficult and complex components. Our process equipment and automated assembly lines are designed with modern prevention and detection methods which help to ensure product quality. Our press lubrication and scrap systems have been designed with the environment in mind— positioning us as an industry leader in waste reduction and steel recycling.

As the automotive industry has shifted towards cost-effective, light-weight components, we’ve added to our core processes to be able to provide our customers with a single-source solution for their production needs. Our production floor is home to several manufacturing processes, including thread rolling, automated assembly and inspection, projection welding, and MAG welding. Our automated transfer systems and in-die tapping abilities give us increased flexibility in the choice and complexity of the work which we take on.

In 2021, Omex Manufacturing became a subsidiary of Wico Metal Products, a Michigan-based stamping company. However, Omex continues to operate largely as a stand-alone operation rooted in Southwestern Ontario.

Today, Omex Manufacturing has grown exponentially and has established itself as a premier metal stamper and assembler for a diverse group of OEM and Tier 1 automotive customers. We have a world-wide footprint: our products are shipped throughout North and South America, Europe, and Asia. Many of our supplied products perform key functions in the world’s vehicles—adjustable seating mechanisms keep drivers comfortable on every continent; and parking mechanisms are responsible for keeping millions of vehicles stopped and safe when they’re not being driven.

Investing in new and innovative technology has positioned us as a leading manufacturer of difficult and complex components. Our process equipment and automated assembly lines are designed with modern prevention and detection methods which help to ensure product quality. Our press lubrication and scrap systems have been designed with the environment in mind— positioning us as an industry leader in waste reduction and steel recycling.

As the automotive industry has shifted towards cost-effective, light-weight components, we’ve added to our core processes to be able to provide our customers with a single-source solution for their production needs. Our production floor is home to several manufacturing processes, including thread rolling, automated assembly and inspection, projection welding, and MAG welding. Our automated transfer systems and in-die tapping abilities give us increased flexibility in the choice and complexity of the work which we take on.

In 2021, Omex Manufacturing became a subsidiary of Wico Metal Products, a Michigan-based stamping company. However, Omex continues to operate largely as a stand-alone operation rooted in Southwestern Ontario.

OMEX CORE VALUES

Environmental Responsibility

We take our commitment to the environment seriously. Our processes are designed to minimize the impact of our operations on the natural environment, allowing us to divert most of our waste away from landfills.

Employee & Workplace Diversity

Omex prides itself on being a workplace which reflects the changing faces of Canada. We welcome employees from many different backgrounds to our workforce, and value their contributions to our company.

Integrity in Business

We believe that ethical conduct should form the foundation of our relationships with our customers, suppliers, employees, and other stakeholders. We encourage our employees to act with honesty and integrity in everything they do.

Investment in the Future

Modern manufacturing requires modern methods—we believe that investing in cutting-edge technology is the best way to remain cost-competitive in a global market, and is the best way to ensure high standards for product quality and productivity.

Long-Term Sustainability

Our business model prioritizes steady, long-term growth through careful planning and sound technological investments. This model has allowed Omex to withstand tough economic times, and consistently delivers positive returns to our shareholders.

Acessibility

Omex Manufacturing ULC is committed to prioritizing safety, health, and continuous growth of values. We welcome everyone and embrace diversity, following the Accessibility for Ontarians with Disabilities Act (AODA) to provide necessary accommodations. Explore our Multi-Year Accessibility Plan as we continuously enhance our services.